Manufacturer-Trained Detonation and Flame Arrestor Cleaning

Understanding the arrestor your equipment uses is critical to safe inspection and cleaning.

Having your detonation and flame arrestors cleaned, inspected, and serviced, by us as your manufacturer or one of the companies we’ve trained, is key to ensuring you get the best longevity and safest continuous operation out of your equipment. Because we know when a unit has reached the end of its lifespan and needs to be replaced—and when it can be saved.

The Future of Combustion Technology Since 1984

Our equipment is inspired by and for the people who get their hands dirty.

Their safety and ability to work effectively is the motivation behind our constant innovation, and it’s led us to consistently push the standard for combustion technology, like our detonation and flame arrestors, further and further into the future. It doesn’t hurt that we also improve your bottom line in the long-run.

Our detonation and flame arrestors’ innovative design allow for cleaning and restoration where other manufacturers’ arrestors fall flat by requiring replacement. Our equipment saves money, time, and even lives.

Tornado’s Detonation and Flame Arrestors Save You Money

Unlike ours, most arrestors can not be restored once they are clogged.

And unfortunately for you, the client, the cost of replacing them each time is significant.

Tornado’s detonation and flame arrestor designs allows for an internal cleaning success rate of nearly 100% for all elements that are brought to us for inspection and cleaning. Not only do you get professional servicing with the inspection process, but our ability to restore your arrestors to full, safe function means you receive tremendous cost savings. We can bring your existing element back to as-new condition for a fraction of the cost of a replacement arrestor.

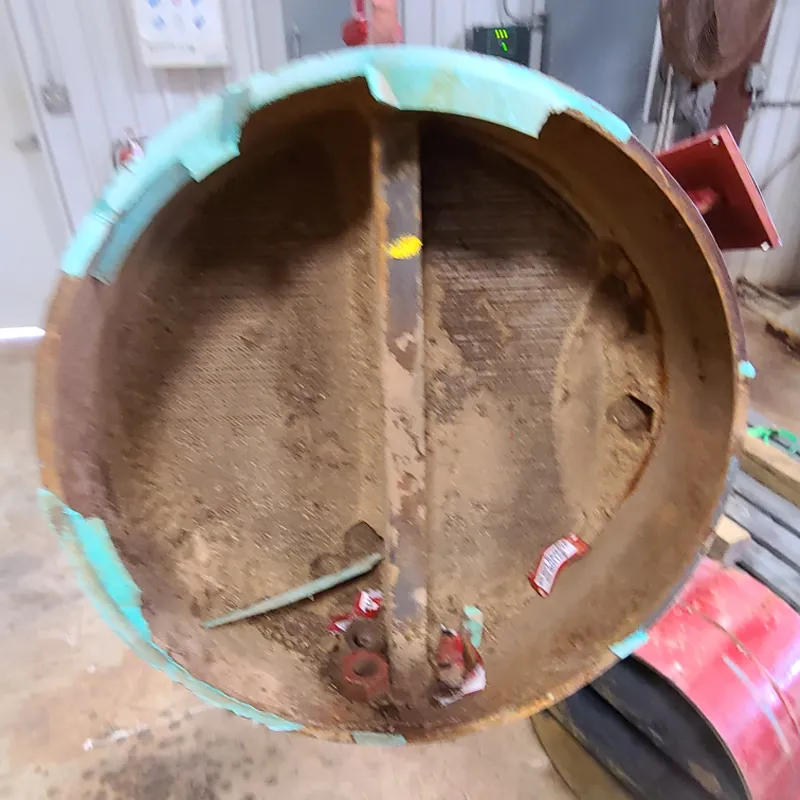

Before and After Cleaning Photos

The following four sliders show examples of arrestors before and after being professionally cleaned. There’s also alternative accessible examples below.

Arrestor before cleaning

Arrestor after cleaning

Arrestor before cleaning

Arrestor after cleaning

Arrestor before cleaning

Arrestor after cleaning

Arrestor before cleaning

Arrestor after cleaning

Why You Shouldn’t Clean Your Arrestor Yourself

Most people attempting to clean a detonation or flame arrestor themselves or hiring a service company to do it for them, don’t realize that it isn’t just a filter.

Washing it isn’t enough. Your arrestors are some of your most important safeguards against dangerous, catastrophic failure of your equipment in the event of flame propagation, which can result in explosions.

When you contact us, or one of the approved service providers we’ve trained on how to inspect and clean our equipment, you’ll receive professional, educated servicing with the inspection process. We never let equipment leave our shop unless we’re certain it will perform efficiently, effectively, and safely.

How Often Should Your Arrestor Be Cleaned and Inspected

Your detonation or flame arrestor should be cleaned and inspected at least once annually to comply with United States Coast Guard and Canadian Standards Association regulations.

If your unit is installed in a high-risk area such as manufacturing facilities for flammable materials or exposed to extreme temperatures or corrosive environments, we’d advise a manufacturer cleaning and inspection every 3-6 months to maintain optimal performance and ensure your workers’ safety.

How to Know When Your Detonation or Flame Arrestor Needs to Be Cleaned

Debris, residue, and corrosion can all contribute to arrestor clogging and failure.

Signs you are overdue for cleaning and inspection include visible rust, particulates, moisture, and other debris as well as unusual noises and vibrations. A clogged element will also restrict vapor flow, resulting in device pressure dropping and process delays.

We recommend visually inspecting the arrestor yourself for early signs of clogging, but there are some cases where the need for cleaning is not immediately apparent without testing. This is why maintaining a regular maintenance schedule is critical to keeping your operations running and your equipment and workers safe.